CONTROL AUTOMATIC PIPE WIPER

Control Pipe Wiper Reduces Pollution and Drilling Fluid Costs

The Control pipe wiper is a pneumatically controlled system that conserves drilling mud and other fluids in oilfield drilling, production and workover operations. With more than ten years’ field use in the United States, Canada and Europe, the Control system has proven its ability to provide improved economy, safety and efficiency in rig floor activities. This system is a major improvement over earlier methods of removing excess fluids from the drill stem.

More Operational Flexibility

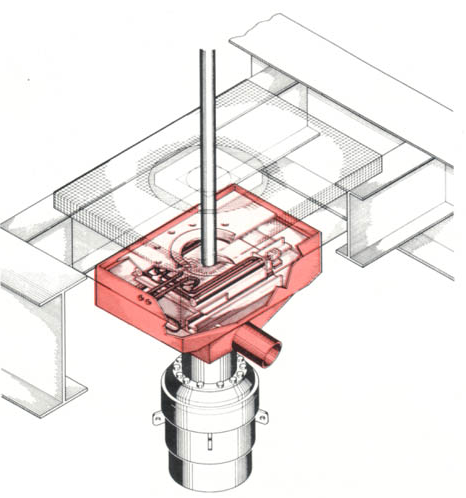

The Control system comprises two overlapping rubber or poly- urethane pads that wrap around the pipe; contact pressure between the pads and the drill string is maintained at any pre-set level by air- actuated cylinders. This variable pressure feature allows large- diameter tools or drilling equipment to be pulled through the pads and wiped clean without causing excess wear or permanent damage to the wiper pads.

Reduced Drilling Fluid and Pipe Wiping Costs

The Control system conserves drilling fluids by effectively wiping all parts of the drill stem when tripping out of the hole and providing a large catch basin beneath the rotary table. The fluids are returned directly to the annulus or to the mud pits through the flow line. Its wiping action is cost-effective, too; while most drill pipe wipers must be discarded after only 1/4″ inch or 1/2″ inch of rubber has worn away, the Control pads can withstand up to 3″ of wear before they must be replaced.

Automatic Hole Cover

The Control system can help prevent unnecessary fishing jobs by serving as a hole cover. Its wiping pads automatically overlap when the drill pipe or tubing is pulled from the hole, effectively stopping any foreign objects from falling into the wellbore. Special units for sucker rod service are available.

Faster, More Efficient Rig Time

Since the Control system adjusts to the various diameters of drill stem components, crews can make complete trips without having to remove the rotary table bushings to pull the pipe wipers. This feature provides significant savings in rig time.

Increased Safety On The Rig Floor

In addition to eliminating the personnel hazards associated with removing and returning rotary bushings, the Control prevents drilling fluids from spilling on the rig floor, the blowout preventer stack or the rig substructure and creating slippery footing in those areas.

Easy Installation

The Control system can be attached to the top of the drilling nipple or the BOP stack or mounted on a track beneath the rotary table for roll-on, roll-off service. All operations are controlled from a console mounted near the driller’s panel.

Control: The Answer To Pipe Wiping Problems

The method of wiping fluid from drill stem and production strings had changed very little since the beginning of rotary drilling – until the introduction of the Control system. Countless hours were spent wrestling with bulky rotary bushings or fighting the mess left from drilling fluids spilled on the rig. Simply stated, the conventional drill pipe wiper is not the most effective way to recover drilling fluids and keep the rig floor clean and safe.

The Control system solves all those problems and more by providing the following advantages:

- Fluid Savings

Conserves costly drilling fluids by preventing mud loss onto the BOP stack, the rig floor or the rig substructure. - Automatic Hole Cover

Overlapping wiping pads prevent dropped wrenches, tong dies, bolts, etc. from entering the wellbore. - Time Savings

Eliminates pulling the rotary bushings since it adjusts to different diameters of various drill stem components. - Personnel Safety

Eliminates hazards associated with pulling the rotary bushings and helps prevent slipping on lost fluids on the rig floor. - Reduces Pollution

Keeps oil based fluids in the mud system where they belong. - Cuts Wiping Costs

The Control pads wear much longer than conventional drill pipe wipers. - Observe Fluid Levels

The Control system can easily be opened to observe fluid levels during tripping operations and in the event of a minor gas kick, the system diverts fluids through the flow nipple.