OVER 45 YEARS EXPERIENCE

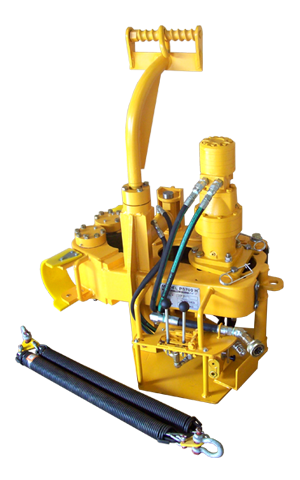

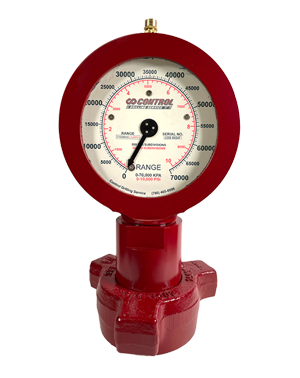

Control Drilling manufactures a number of products used in Canada and internationally. These products are supported with knowledgeable technicians to provide service and a large inventory to provide parts and equipment when required.

OUR SERVICES

Established in in 1987, Control Drilling Services has been at the heart of the Canadian oil and gas industry for over 45 years. For almost 5 decades we have provided specialized instrumentation services and solutions to the international drilling and well servicing markets. Located in Edmonton, Alberta, Control drilling is family owned and operated, and most of our parts are made locally at our in house manufacturing plant. We have a team of exceptionally knowledgeable technicians and sales people happy answer any questions you might have. With a 24/7 365 day a year on call setup, someone will always pick up the phone to provide the great service Control Drilling is known for!